Intelligent compaction systems (ICS) are powerful tools, which provide the operator with valuable data in real time to increase the quality and efficiency of compaction works. After these tools, point-by-point methods to identify areas of inadequate construction became obsolete. The new systems provide Road Agencies much more accountability in quality control and, consequently, greater road service life. At the same time, they increase the construction efficiency, as they indicate the operator when the compaction work is complete, moving to the next one in the optimum moment.

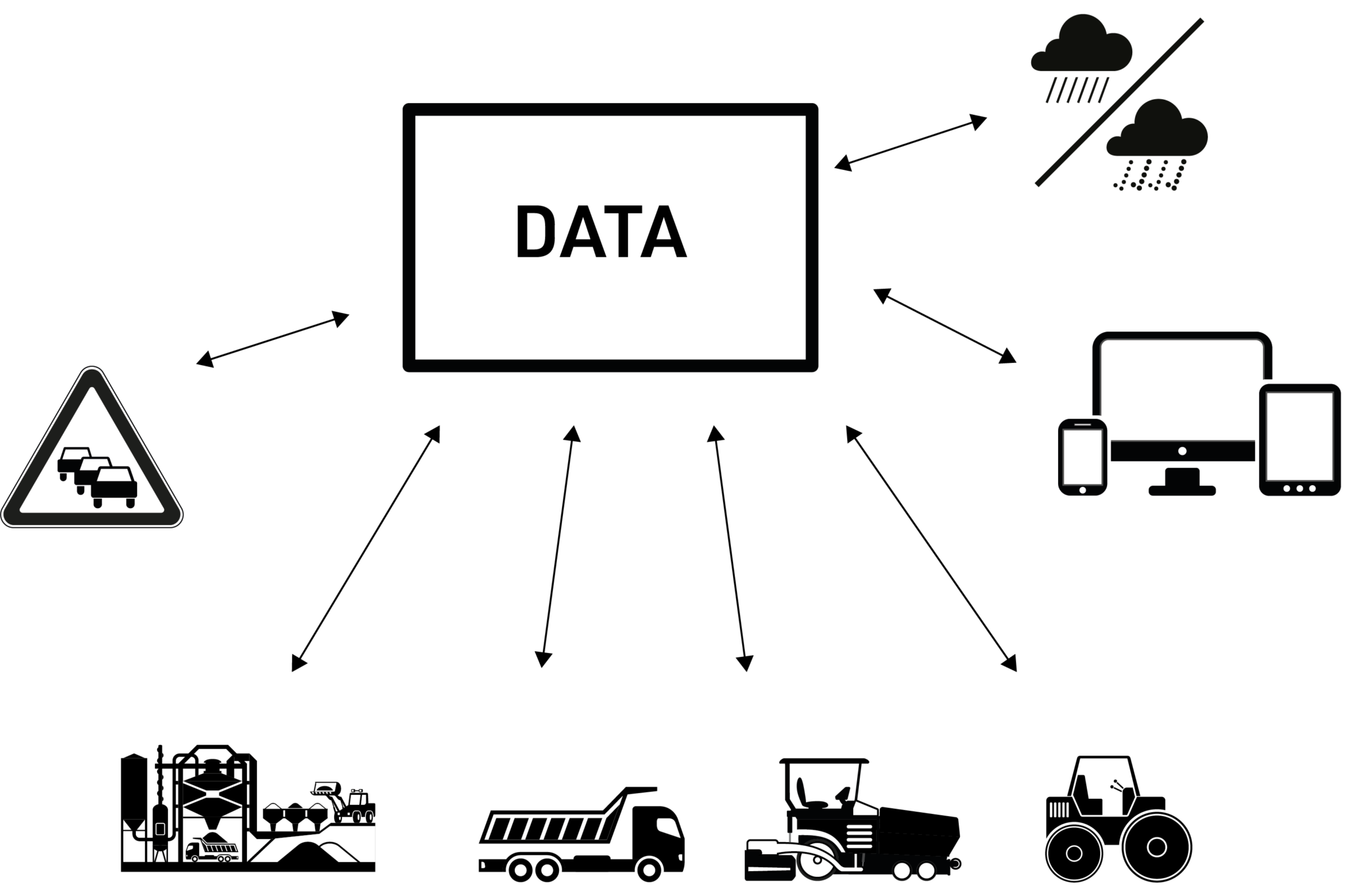

These systems integrate:

- Monitoring systems to measure work site conditions in real time (number of passes, pavement stiffness, temperature, humidity, etc.)

- Global navigation satellite systems, which allow operators, supervisors and engineers to record and visualise the quality and uniformity of the work over the entire site

- Analysis software able to automatically identify and document hidden efficiencies.

Instead of traditional methods, which analyse the compaction level of the material based on its density, modern ICS use accelerometers to measure the stiffness, or the ability of the material to resist deformation. This mechanical property is more related to the actual bearing capacity of the layer, rather than the density. With this value being continuously monitored, the operator simply needs to execute compaction passes until the required stiffness has been reached. At this point, the testing crew check the section and the compactor is moved to the next area.

Virtual indication of number of passes by smart roller compactors

Modern machines also incorporate auto adjustable compactions systems to automatically apply the optimal amount of compaction force and vibration amplitude for the material and conditions of the work. From higher loads for faster results to lower loads, which eliminate de-coupling and damage to asphalt layers or help when compacting near sensitive structures.

Air-purged dual infrared temperature sensors, mounted on the front and rear of the machine, eliminate the need of hand-held devices and provide real-time temperature maps of the compacting asphalt, minimising inaccurate readings caused by debris on sensors. They keep the operator informed of the material conditions and indicate when compaction must start or stop.

Finally, all the data (e.g. number of passes, stiffness, temperature, etc.) is geopositioned into real time maps that can be used for documentation and quality control. Depending on requirements, different technologies can be integrated, to obtain resolutions of up to 1 and 2 cm in the horizontal and vertical axis respectively.