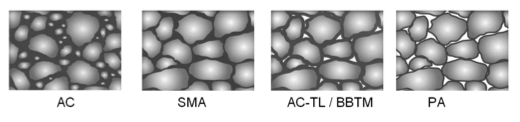

Different asphalt mixtures are available for the top layer of an asphalt road. The top layer is normally called the “surface course” and the type of surface course mixture chosen depends on the requirements for the road surface.

The surface course constitutes the top layer of the pavement and should be able to withstand high traffic- and environment-induced stresses without exhibiting unsatisfactory cracking and rutting in order to provide an even profile for the comfort of the user and at the same time possessing a texture to ensure adequate skid resistance. Depending on local conditions, functional characteristics such as skid resistance, noise reduction and durability are often required for surface courses. In some cases, rapid drainage of surface water is desired through a porous surface while in other cases the surface course should be impermeable in order to keep water out of the pavement structure. As indicated, the surface layer is important for the pavement performance but no single material can provide all the desired characteristics (e.g. porous and impermeable at the same time). A wide range of surface layer products can therefore be considered appropriate depending on specific requirements:

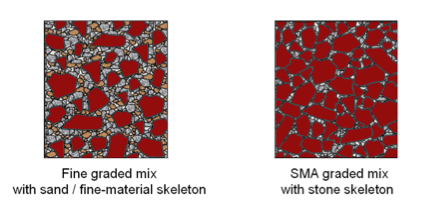

- Asphalt Concrete (AC)

- Very Thin Layer Asphalt Concrete (Béton Bitumineux Mince) (BBTM)

- Asphalt for Ultra-Thin Layers (AUTL)

- Stone Mastic Asphalt (SMA)

- Hot Rolled Asphalt (HRA)

- Porous Asphalt (PA)

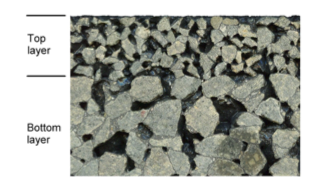

- Double layered Porous Asphalt (2L PA)

- Mastic Asphalt (MA)

- Soft Asphalt (SA)

The selection of the surface course is a matter of identifying the most appropriate material during the design process. The functional requirements can conflict. For example, noise reduction could require the use of a double-layered porous asphalt and that conflicts with the requirement of a very durable surface layer. The durability of surface layers can be improved by using higher quality materials. The higher costs of these will be compensated by the lower costs of traffic measures and user costs.